What is silicone heat transfer

Silicone heat transfer is a popular new technology in recent years. It is to smear silicone or use a dispenser to spread silicone on the mold, place the mold on the hot plate of the vulcanizer, paste hot-melt paper, and use the vulcanizer to apply it. It is a process of hot pressing for about 10-20 seconds, taking out the mold and sticking the required LOGO and pattern with high-stick paper.

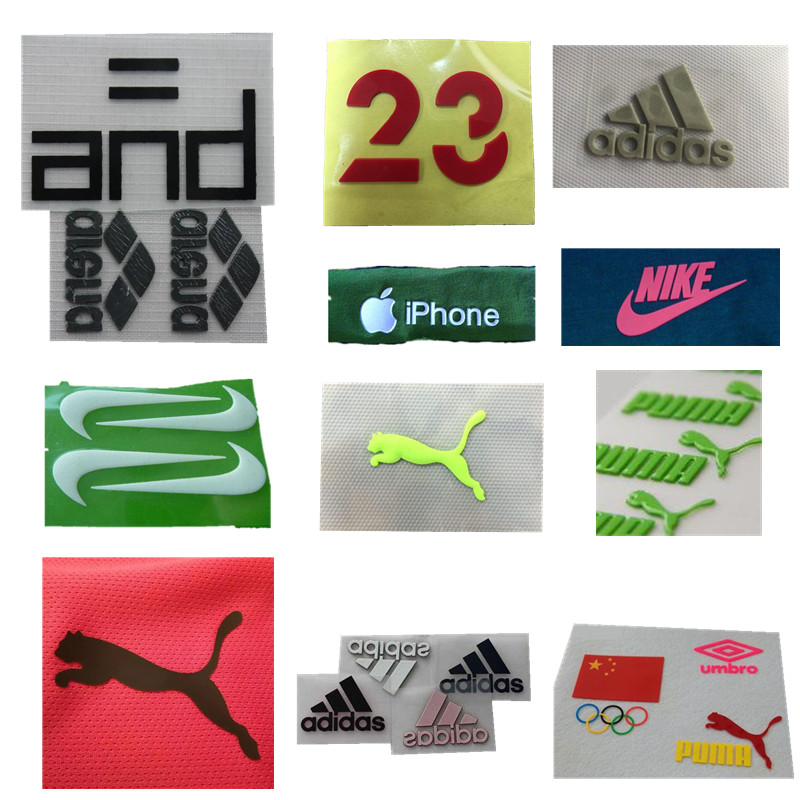

Silicone heat transfer is very versatile, and the silicone molds produced can be used in team uniforms, gloves, company LOGO, clothes, hats, shoes, etc.

Silicone heat transfer process

1. Prepare materials, mix liquid silicone, curing agent, and color paste in a certain proportion.

2. Vacuum the adjusted material with a silicone vacuum machine. This step is mainly to remove the air bubbles in the silicone material, so that the finished silicone product has no bee eyes, no dents, and is smooth and smooth.

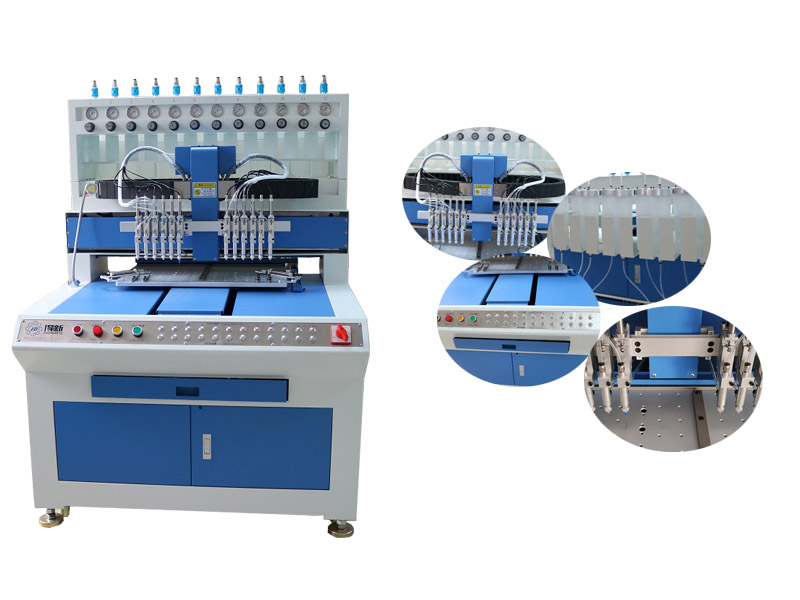

3. Program the program on the automatic dispensing machine, and then put the vacuumed raw materials and molds on the dispensing machine for accurate dispensing.

4. Paste Teflon on the upper and lower heating plates of the silicone in-mold transfer vacuum vulcanizer, set the required temperature and parameters in advance, and turn on the preheating to make the working area reach the required temperature. Cover the glued mold with a layer of hot melt glue, place it on the heating plate under the transfer vacuum vulcanizer in the silicone mold, and then cover it with a piece of Teflon. Start the machine for vacuuming and vulcanization molding.

5. Use a thermal insulation tool to remove the mold and place it on the workbench, carefully remove the Teflon and hot melt adhesive mold while it is hot, and use a pick to pick out the useless waste, and cover with a low-viscosity thermal transfer mold , After rubbing it back and forth with a cloth, place it on a freezing table for cold molding, which is easy to demould. When the mold still has a little residual temperature, quickly remove the mold and place it on the workbench.

6. Tear off the low-viscosity thermal transfer mold, stick the solid silicone on the mold, and tear it up in accordance with the pattern position, and it cannot be displaced.

7. Cover the silicone trademark on the low-viscosity mold with a high-viscosity heat transfer mold of the corresponding size, stick the silicone label on the high-viscosity heat-transfer mold, tear off the low-viscosity heat-transfer mold, and then heat transfer the silicone label has been finished.

Post time: Jul-11-2023