Concave-convex embossing is a way to attach patterns to leather or textiles with a high wave cycle, and the concavo-convex embossing is three-dimensional. It is mostly used on the logos of some suitcases and clothing, which gives people a three-dimensional effect and also highlights their own brand trademarks.

Silicone embossing has a very important feature, that is, environmental protection. Not only will it not affect the environment, but it is not harmful to the human body. It is a non-toxic and tasteless product, and the trademark on the silicone embossing machine is not only its own It is not easy to fall off, nor can it be buckled down. The adhesion is very strong, and it also has a strong three-dimensional effect. It is an embossing process often used by many luggage and clothing manufacturers.

Silicone embossing machine can be widely used in clothing, gifts, trademarks and other industries. It is mainly used in the production of clothing, leisure, sports, T-shirts, jeans, children’s wear, webbing, socks, gloves, and various crafts. The main purpose is to To environmental protection, it is the industry’s first silicone embossing equipment

What is embossing machine?

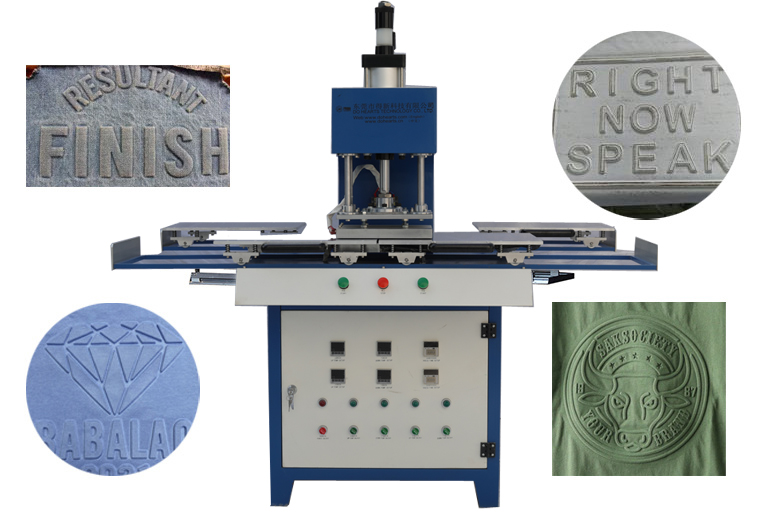

The embossing machine is mainly used for embossing, embossing, creasing, and embossing trademarks on various fabrics. It can also emboss trademarks on non-woven fabrics, coatings, artificial leather, paper, aluminum plates, imitation leather patterns and various shades. pattern, pattern.

Clothing fabric embossing machine, concave-convex mold matching embossing processing equipment is the latest generation of embossing machine equipment in China. Using the principle of embossing machine, the thermocouple temperature control digital display is used to control the upper and lower heating. The male and female molds are installed on the heating work plate. With a certain amount of pressure, the purpose of embossing can be fully achieved. The 3D concave-convex effect of the pattern is obvious, and the production efficiency is high. The mold can also be changed at will according to customer needs, and patterns of different patterns and effects can be pressed out. It is essential for the production of clothing fabrics, curtain fabrics, sofa fabrics, leather 3D embossing, decorative soft bags, and leather bronzing embossing. equipment.

Garment fabric embossing machine, embossing machine for embossing and embossing processing equipment for embossing and embossing equipment Embossing processing equipment.

the

Silicone embossing machine application

Clothing embossing, logo, watch strap, vamp embossing, flocking embossing, denim embossing, automotive interior, shoe products, all kinds of bags, handbags, leather, etc. embossing embossed patterns and letters. Such as hot embossing of shoes and hats, clothing embossing, trademarks, bags and so on.

The principle of silicone embossing machine

The silicone embossing machine mainly uses the working principle of electric heating and temperature control, and uses a heating tube to heat the surface of the embossing mold. Coat the surface of the leather with glue, and then use the shape of the embossing mold to add a certain amount of pressure to achieve a perfect embossing effect. Mainly used for clothing embossing, denim embossing, shoe embossing, trademarks, leather bags, car cushions, craft gifts, bags, and denim clothing.

Silicone embossing process

Silicone embossing is mainly to press silicone materials on different fabrics to form 3D concave-convex textures in different colors and shapes.

Manufacturing process steps:

.Drop silicone on the mold

.It is directly bonded to the fabric, heated by a machine for pressing, and the finished product is completed.

the

With the arrival of 2022, people’s living standards continue to improve. Whether it is more and more pursuit of high quality in terms of food and accommodation, or the requirements for clothing are getting higher and higher, the embossing of clothing can better publicize individuality and release youth. At the same time, it is sought after by many young people.

the

How to make clothing embossing?

1. Prepare the corresponding mold, a total of two pieces, the pattern is the same, divided into concave mold and convex mold.

2. Concave-convex embossing for clothing, with heating function, the pressure should be high when pressing, so as to target different materials of fabrics.

3. Turn on the embossing machine, and adjust the temperature and pressing time of the upper and lower pressure plates respectively. The corresponding pressing pressure, temperature and pressing time of fabrics of different materials are also different, and it will take a lot of time. Practice and master it.

4. Wait until the pressure plate is heated to a certain temperature. Spread the cloth on the surface of the die, and then cover the punch on the cloth. Pay attention to the alignment between the two dies, otherwise the die will be easily damaged.

6. Put the mold on the lower temperature plate of the embossing machine, start the machine, press down, and after pressing for 4 seconds, the upper and lower heating plates will be separated automatically, and the concave and convex molds will be separated, and the fabric will be removed, which is a complete finished product.

Post time: Jun-23-2023