First step,liquid silicone coloring: The raw material of liquid silicone is transparent, add a certain proportion of color paste, curing agent, and diluent, stir evenly and put it aside. Several colors need to be used, and operate according to this method.

Second step, Liquid silicone vacuuming: put the adjusted color silicone into the vacuum machine, vacuumize to remove the air bubbles inside, and then pour it into the syringe of the dispensing machine for standby.

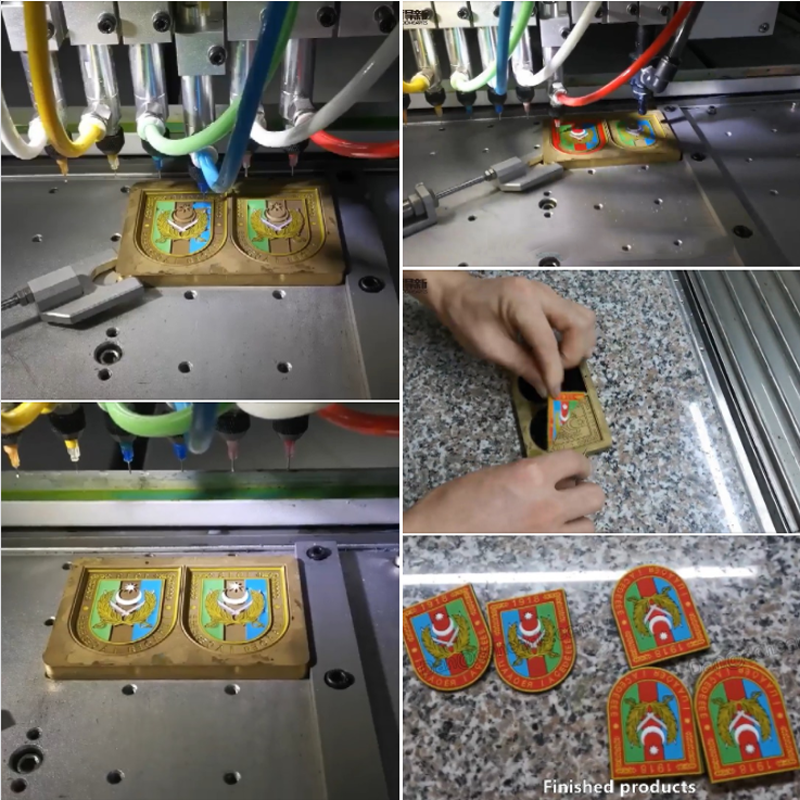

Third step, Programming and dispensing of silicone glue dispensing machine: place the mold on the glue dispensing table, program according to the color requirements, start the silicone glue dispensing machine, and dispense liquid silicone on the mold according to the color requirements.

Fourth step,Liquid silicone drying: put the liquid silicone mold into the oven for drying and setting.

Fifth,solid silicone color refining: take an appropriate amount of solid silicone raw material, put in a certain proportion of vulcanizing agent, release agent and color paste, and use a rubber mixing machine for rubber mixing.

Sixth step,Material cutting machine cutting: cut the refined solid silica gel into strips as required.

Seven step,Vulcanizing machine vulcanization molding: solid silicone is filled into the mold, and then the mold is closed and put into a flat vulcanizing machine for vulcanization molding. Tear off excess scraps and the multi-color logo is complete.

Post time: Dec-22-2022