The production process of 3D soft rubber keychain can be divided into the following steps: design, mold making, dispensing and molding, and packaging.

Design

During the design stage, the pattern and shape of the keychain are designed according to customer needs, and the materials and colors used are determined.

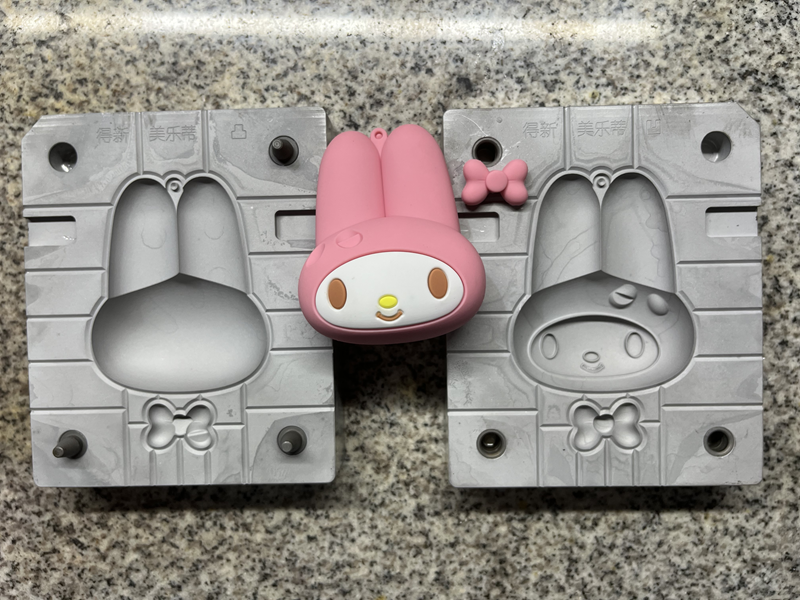

Mold making

Molds are made according to the design drawings to ensure the accuracy and durability of the mold. Mold making is a key step to ensure mass production, and it needs to be engraved with a mold engraving machine.

Dispensing and molding

The soft rubber material is mixed with a mixing machine, and then the soft rubber material is injected into the mold with a dispensing machine. If it is a single-sided soft rubber keychain, it can be molded after heating in an oven and cooling. If it is a double-sided 3D soft rubber keychain, use automatic molding machine to make it . This step requires controlling the temperature and time to ensure the quality and appearance of the keychain.

Dispensing machine and oven

Molding machine

Packaging

The 3D soft rubber keychain is packaged for sale and transportation. The packaging design needs to be simple and beautiful, and it is also necessary to consider protecting the product from damage.

Post time: Nov-01-2024