Dispensing technology is used more and more in the processing and manufacturing industry, and the requirements are becoming more and more stringent. Manual dispensing will not be able to meet the needs of the industry and will gradually be replaced by automatic dispensing machines, which are widely used in processing and manufacturing industries, such as integrated circuits, printed circuit boards, electronic components, auto parts, etc. The automatic dispensing machine can realize three-axis linkage and intelligent work at the level of automation. The automatic dispensing machine greatly improves work efficiency and improves product quality.

Generally, the repeatability error value of the dispenser is relatively small. When the error of the product or the error value of the setting exceeds the accuracy of the dispenser, the quality of the dispensing will be seriously endangered every time the product is replaced, because most of the dispensing methods are contact dispensing, and the glue dots on the dispensing tip should be Touch the surface of the product to complete the dispensing.

Why choose automatic dispensing machine?

1. Manual dispensing is not accurate

Manual dispensing operation, resulting in unstable quality, low pass rate, poor consistency, unable to produce in large quantities

2. Personnel control

Worker mobility causes increased training and management costs and low work efficiency

3. Production adjustment

In the off-season and peak season, when the order volume is obviously large, the workers cannot keep up with the order, and when the order is small, manpower is wasted

4. Market competition

Raw materials continue to rise, prices continue to be lowered, profit margins become smaller, and competition is fierce

5. Glue ratio

The manual ratio of glue is uneven, the error rate is seriously wasted, it is not easy to clean, and it is time-consuming and laborious

6. Scale and strength

When big customers come to the factory, the factory does not have advanced equipment and technology, so it cannot reflect its strength

7. Development trend

Automated factories have become the future trend. The use of automated equipment will effectively improve production efficiency, reduce production costs, shorten production cycles, and improve business efficiency for you.

The emergence of automatic dispensing machines has created conditions for the production needs of high performance and high indicators, but different processes require different equipment, so how to choose a fully automatic dispensing machine that suits you and is cost-effective?

First of all, you should combine your actual situation. If you need high precision and large output, you can consider choosing a multi-head visual dispensing machine. At present, there are up to six dispensing machines on the market. You can choose according to your own needs. If There is no special need to choose an ordinary glue dispenser. Ordinary automatic glue dispensers can meet the needs of many aspects. Since the operation is in Chinese, it is quick to use and easy to operate. The workers in the production line can quickly learn to operate and get on the machine, using the man-machine platform interface, the operation is intuitive and convenient.

Let’s talk about the purchasing skills of dispensing machines.

1. Accurate positioning of glue characteristics: general glue uses a single-component glue dispenser, AB glue uses a double-liquid glue dispenser, PU glue uses a PU glue dispenser, UV glue uses a specific syringe, etc.

2 Dispensing process requirements determine equipment: The dispensing machine is mainly composed of a motion module unit + a glue volume control module unit. The production capacity of the product is small, and manual pneumatic dispensing can be used if power is not sought; if high-precision control of the glue output is required, a mechanical dispensing machine with powerful automatic functions is selected.

3. The cost budget determines the type selection: a certain glue needs to use a very high-priced machine, and you can consider replacing the glue.

Finally, to choose a dispensing machine, you need to judge its quality first, and you should start from many aspects. Secondly, look at the appearance. A good product is flawless and exquisite in appearance. After turning on the power, observe whether the prompt light is on or off. When debugging and observing, whether the state is smooth and the dispensing effect is good. The more accurate the timing of the dispensing machine, the higher the price of the machine, the more accurate the quantification, and the lower the error. It is necessary to clarify the dispensing needs before purchasing.

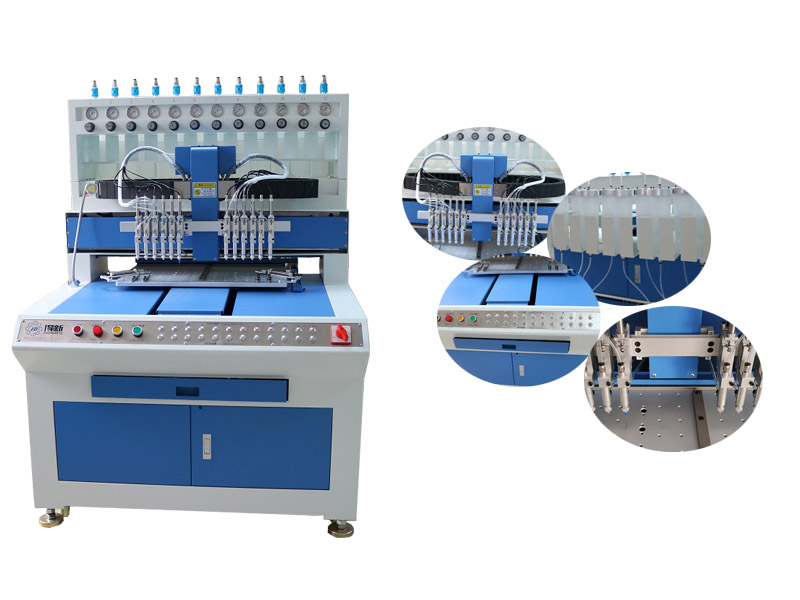

Of course, it is also very important to choose a company that manufactures dispensing machines. Our company is a professional dispensing machine manufacturing company that can provide 6-color, 12-color, and 18-color dispensing machines. Dongguan Dohearts Technology Co., Ltd. is a company with 20 A company with years of research and development experience in dispensing machines and PVC equipment, not only provides PVC/silicone equipment, but also provides one-stop services such as various raw materials, mold engraving, etc.

Post time: Jun-30-2023