In today’s competitive market, branding plays a crucial role in establishing a company’s identity and attracting customers. One of the most effective ways to enhance brand recognition is through the application of logos on various products and materials. Wide bands, such as wristbands, belts, and watch straps, offer ample space for displaying logos prominently. To streamline and automate this process, the introduction of automatic silicone 3D logo coating machines has revolutionized the industry. This article delves into the features, benefits, and applications of these advanced machines.

Efficiency and Precision:

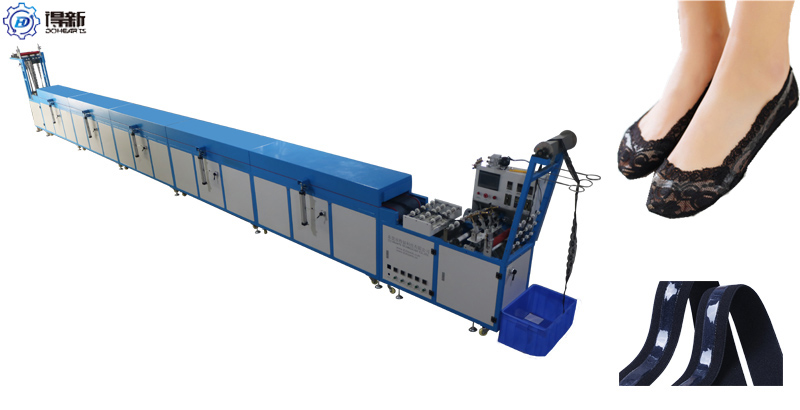

The automatic silicone 3D logo coating machine for wide bands is designed to optimize the logo coating process, ensuring efficiency and precision. Equipped with cutting-edge technology, these machines offer a seamless and consistent application of silicone coatings onto wide bands. The automated process eliminates the need for manual labor, reducing production time and costs significantly.

Features:

- Advanced 3D Logo Coating: The machine utilizes a 3D logo coating technique, enabling the creation of raised and textured logos on wide bands. This technique adds depth and dimension to the logo, enhancing its visual appeal and making it stand out.

- Customization Options: The machine allows for the customization of logo designs, accommodating various shapes, sizes, and colors. This flexibility enables businesses to create unique and eye-catching logos that align with their brand identity.

- High-Speed Operation: With its automated system, the machine can coat multiple wide bands simultaneously, ensuring a high production rate. This feature is particularly beneficial for businesses with large-scale logo coating requirements, allowing them to meet tight deadlines without compromising quality.

- Consistent Coating Thickness: The machine guarantees an even and consistent coating thickness across all wide bands. This precision ensures that logos appear uniform and professional, enhancing the overall aesthetic appeal of the products.

Benefits:

- Time and Cost Savings: By automating the logo coating process, businesses can save a significant amount of time and labor costs. The machine’s high-speed operation and efficiency allow for increased productivity, ultimately leading to higher profitability.

- Improved Quality Control: The automated process eliminates the risk of human error, resulting in consistent and high-quality logo coatings. This level of precision enhances the overall product quality, instilling confidence in customers and reinforcing brand reputation.

- Enhanced Branding Opportunities: With the ability to create customized and visually appealing logos, businesses can effectively differentiate themselves from competitors. The raised and textured logos produced by the machine add a luxurious and professional touch to wide bands, attracting attention and leaving a lasting impression on customers.

Applications:

The automatic silicone 3D logo coating machine finds extensive applications across various industries, including fashion, sports, and promotional merchandise. It is particularly suitable for logo coating on wide bands such as wristbands, belts, watch straps, and headbands. The versatility of the machine enables businesses to cater to diverse customer demands, expanding their product offerings and market reach.

Conclusion:

The automatic silicone 3D logo coating machine evolutionizes the logo coating process, offering efficiency, precision, and customization options. By automating this essential branding step, businesses can save time and costs while ensuring consistent and high-quality logo coatings. With its ability to create visually appealing and textured logos, the machine opens up new branding opportunities, making wide bands stand out in the market. Embracing this advanced technology allows businesses to strengthen their brand identity, attract customers, and gain a competitive edge in the industry.

Post time: Aug-18-2023