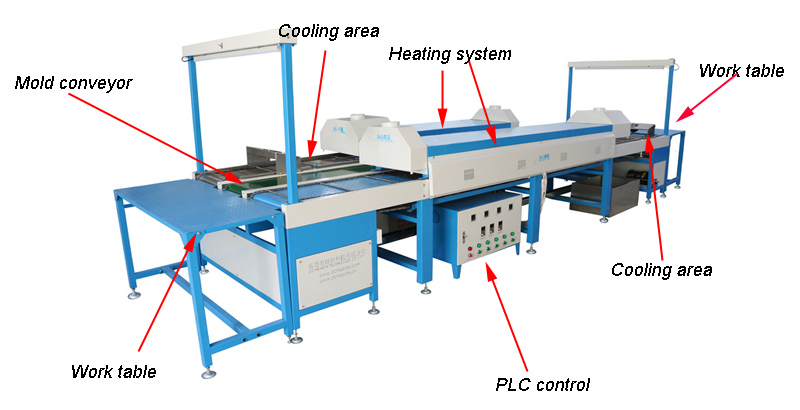

Automatic pvc production line for heating and cooling

Description

The automatic production line has a simple structure and is mainly composed of worktable, baking area, cooling area, and mold conveying area. It is suitable for producing large-size PVC products and has relatively highly productive factories. The whole machine is designed according to the production line operation method, which greatly improves productivity and saves a lot of labor. The left and right sides are equipped with working tables, which are convenient for taking and placing molds. Brand PLC control, easy to operate. It is suitable for products with few styles and high production.

Features

1. Automatic heating and cooling system

2. With semi-automatic base color dispensing

3. Lower power, saving labor

4. According to demand can add embossing functions, automatic mold return functions, automatic dispensing systems, and other functions.

Specification

|

Model |

DH-E02 |

|

Max size of mold |

340*340mm(length adjustable) |

|

Conveyor belt width |

300 mm |

|

Total power |

34KW |

|

Actual power consumption |

20KW |

|

Voltage |

380V/220V |

|

Weight |

1400 KG |

|

Dimension |

L6000*W1450*H1600 |

Application

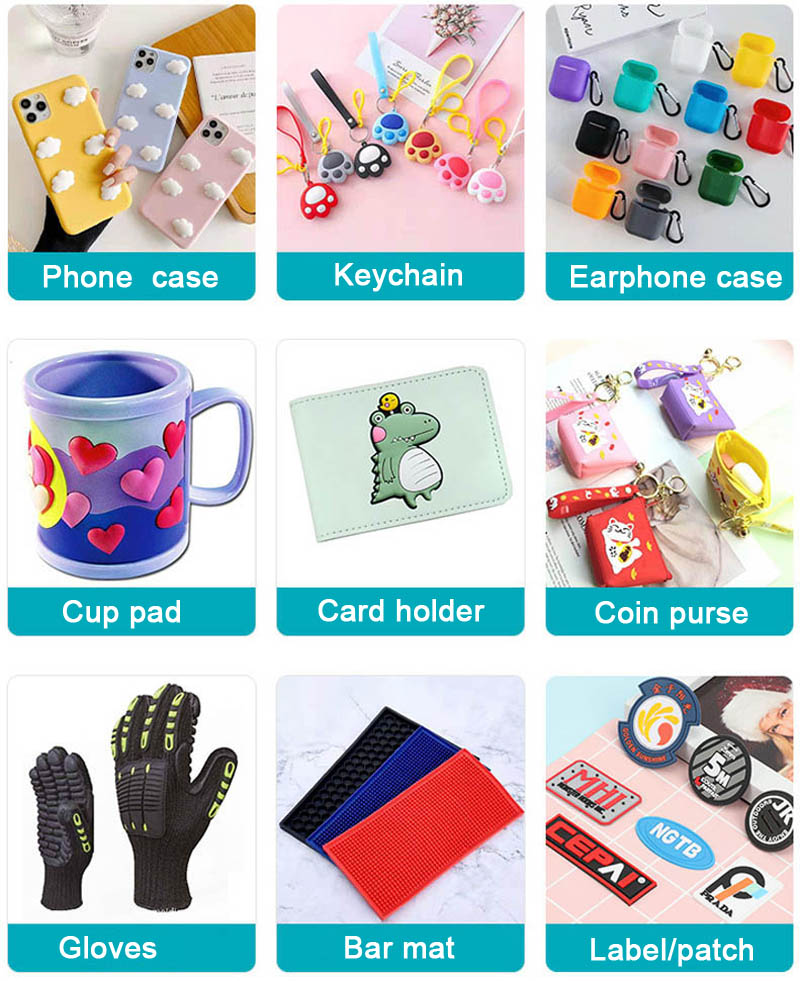

Automatic production line is mainly used to make labels, gifts, safety labels, trademarks, keychains, car mat, cup lid, cup mat, cloth label, foot mat, photo frames, mouse mats, bar mats, phone holder, gloves, bar mat, badge, fridge magnet, crafts, bottle opener, cartoon doll, promotion gift, watch belt, sticker, etc.

Q: How many pieces of product can production one day?

A: The production depends on the size, design and colors of the product.If produce a small label, it can produce about 25,000pcs a day

Q:Could you supply supporting machines?

A:Yes,we can supply mold,raw material,matering mixing machine,vacuum machine,baking machine and automatic production line.

Q:Could you support sample service?

A:Yes,free sample service.

Q: Could you support training, installation and commission service?

A:Yes, free training, install and commission service